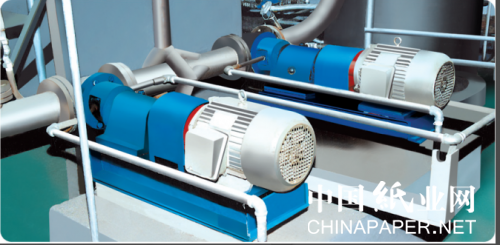

ZTH系列中浓混合器/ ZTH Series Medium Consistency Mixer

用 途:

用于制浆造纸行业中浓漂白工段中,将化学药品、蒸汽与浆料得到充分均匀混合。

结构特点:

采用三叶片高效转子,转子高速旋转使浆料流态化,破坏了纤维网络结构,达到最佳混合效果。带螺旋筋的内壳结构,避免浆料在壳体内滞留,减少了压力损失。

转子旋转方向与浆料流动方向垂直,避免了漂剂的离析逸出,节省化学药品。与浆料接触零件采用不锈钢材料,使用寿命长。

进出浆口可在水平或垂直方向调整,安装、布置方便。

串联于中浓泵之后,动力消耗低,与相同混合效率下的其它混合器相比,能耗节省80%。

Application:

The medium consistency mixer is used in medium consistency bleaching section

of stock preparation process. It mixes chemicals, steam and pulp fully.

Design Features:

Adopt triple-blade rotor which helps in working efficiently. High speed

rotation of rotor makes stock fluidization and destroys the network structure of

fiber. It reaches the best mixing result.

By adopting inner shell structure with spiral hooping avoids stock detaining

in the shell and reduces pressure loss; The rotation direction of rotor is

perpendicular to the flow direction of stock. It prevents bleaching agents from

eduction and overflowing and saves chemicals;

It extends service life since parts contacted with pulp are made by stainless

steel;

Inlet and outlet port can be adjusted on horizontal or vertical direction. It

is simple to install and layout.

It lowers power consumption by cascading after M.C pump. Compared with other

mixers, it can save 80% power.

主要技术参数 / Main technical data

|

规 格 Size

|

DN80

|

DN100

|

DN125

|

DN150

|

DN200

|

|

适用温度Working Temperature(℃)

|

≤120

|

≤120

|

≤120

|

≤120

|

≤120

|

|

处理浓度Working Consistency(%)

|

8~14

|

8~14

|

8~14

|

8~14

|

8~14

|

|

工作压力Work Pressure(MPa)

|

≤0.6

|

≤0.6

|

≤0.6

|

≤0.6

|

≤0.6

|

|

生产能力Capacity (t/24h)

|

25~40

|

80~120

|

160~200

|

210~260

|

350~400

|

|

电机功率Motor Power (KW)

|

5.5

|

11

|

18.5

|

22

|

37

|

苏公网安备 32010202010716号

苏公网安备 32010202010716号