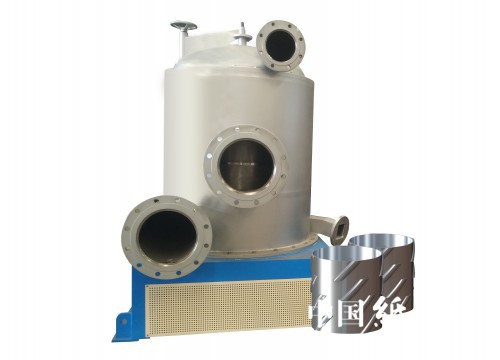

ZSN系列升流式压力筛/ ZSN Upflow Pressure Screen

用 途:

可用于化学木浆、化学草浆、各类废纸浆、机械木浆等多种原料的筛选工艺流程。用于浆料制备过程,作为各类浆料漂白前或漂白后的筛选设备。作为纸机前浆料的精筛选。

结构特点:

使轻杂质与浆料中的空气自然上升到顶部排渣口迅速排出机外。重杂质沉降到底部排出减少了转子和筛框的磨损。升流式结

构消除了造成筛体振动和应力的涡流。升流形式有效地避免了杂质重新混入进浆之中。生产能力大,对各类浆料适应性广。进 浆浓 度 适 应 范 围 大 ,适 用 于 中

浓进浆 (2%~3.5%), 亦适用低浓进浆 (0.5%~1.2%)

下部进浆上部出浆的结构形式,解决了粗杂质在筛区停留时间长和被重新混入进浆中的缺点。减少了转子和筛框损坏的可能。

消除了造成筛体振动、摇动和应力的涡流,减少了增浓现象。

筛鼓、转子的清洗、调节、检查、拆卸均很方便。配有多种形式的转子。

Application:

Due to features of impurities in waste paper, the structure of this pressure

screen is specially designed as upflow screen, which is more suitable for coarse

screening for waste paper.

Design Features

pulp flows into pressure screen from lower parts and flows out from the upper

parts, which solving the problem of coarse impurities staying too long in the

screening part and then easily mixed with clean pulp again, reducing the damage

to rotor and screen basket, removing the turbulence which bring out vibration,

shaking and movement stress of pressure screen, reducing appearance of

consistency increase during screening

The structure design helps in easily washing, adjusting, checking and

removing rotor and screen basket. The screen can work with

different design of rotors.

技术参数 / Technical Data

|

型号

|

筛选面积(m2)

|

进浆浓度(%)

|

进浆压力(MPa)

|

筛孔规格(mm)

|

生产能力(t/24h)

|

电机功率(KW)

|

|

Model

|

Screen Area(m 2)

|

Inlet Consistency(%)

|

Inlet Pressure(MPa)

|

Screen Hole Size(mm)

|

Capacity(t/24h)

|

Motor Power(KW)

|

|

ZSN61

|

0.5

|

1.2-3.5%

|

0.15-0.3

|

孔径:ϕ 1.2~ϕ 2.5 缝隙:

0.3-1.2

|

15~40

|

18.5-45

|

|

ZSN62

|

1.0

|

1.2-3.5%

|

0.15-0.3

|

30-80

|

45-90

|

|

ZSN63

|

1.5

|

1.2-3.5%

|

0.15-0.3

|

45-120

|

55-110

|

|

ZSN64

|

2

|

1.2-3.5%

|

0.15-0.3

|

60-160

|

75-160

|

|

ZSN65

|

2.5

|

1.2-3.5%

|

0.15-0.3

|

75-200

|

90~200

|

|

ZSN66

|

3

|

1.2-3.5%

|

0.15-0.3

|

90-240

|

110-250

|

|

ZSN67

|

4

|

1.2-3.5%

|

0.15-0.3

|

120-320

|

160-315

|

生产能力和电机功率说明:压力筛的生产能力其确定值由浆种、浓度、筛框的开孔率、浆流速等技术参数计算生成。电机功率根据实际产能确定。

Notes: the capacity in sheet is calculated and considered based on pulp type,

working consistency, hole opening area of screen basket, flow velocity. The

motor power shall be subject to the actual capacity.

苏公网安备 32010202010716号

苏公网安备 32010202010716号